Say Cheese! A Brief History

The art of cheesemaking dates back at least 5,000 years. Evidence exists of cheese first being made in ancient Egypt.

The production of cheese, as a food preservation process, allows the value of the milk to be preserved, from a nutritional and economical perspective. This allows us to choose when to enjoy the cheese (within limits, of course). And, with more specialised processing comes greater economic value.

It may surprise you to learn that cheesemaking was probably discovered by accident, like so many modern food processing methods.

Nomadic herdsmen started milking their livestock. A need arose to store that which they could not consume right away. Milk sacs were made from the stomachs of goats and sheep. The stomach linings contain rennet, wild bacteria and lactic acid, causing the milk to coagulate and ferment. The sun’s heat certainly also played its part in this process. A type of yogurt would have been produced in this way.

Once gentle agitation and the separation of curd from whey were added, this would have resulted in the production of cheese, consisting mainly of the major milk protein – casein – and milk fat.

Production of

Cheese & Yogurt

Cheese is the most complex of the dairy products, involving chemical, biochemical and microbiological processes. Broadly speaking, cheesemaking requires milk acidification, coagulation, whey removal, packaging and storage.

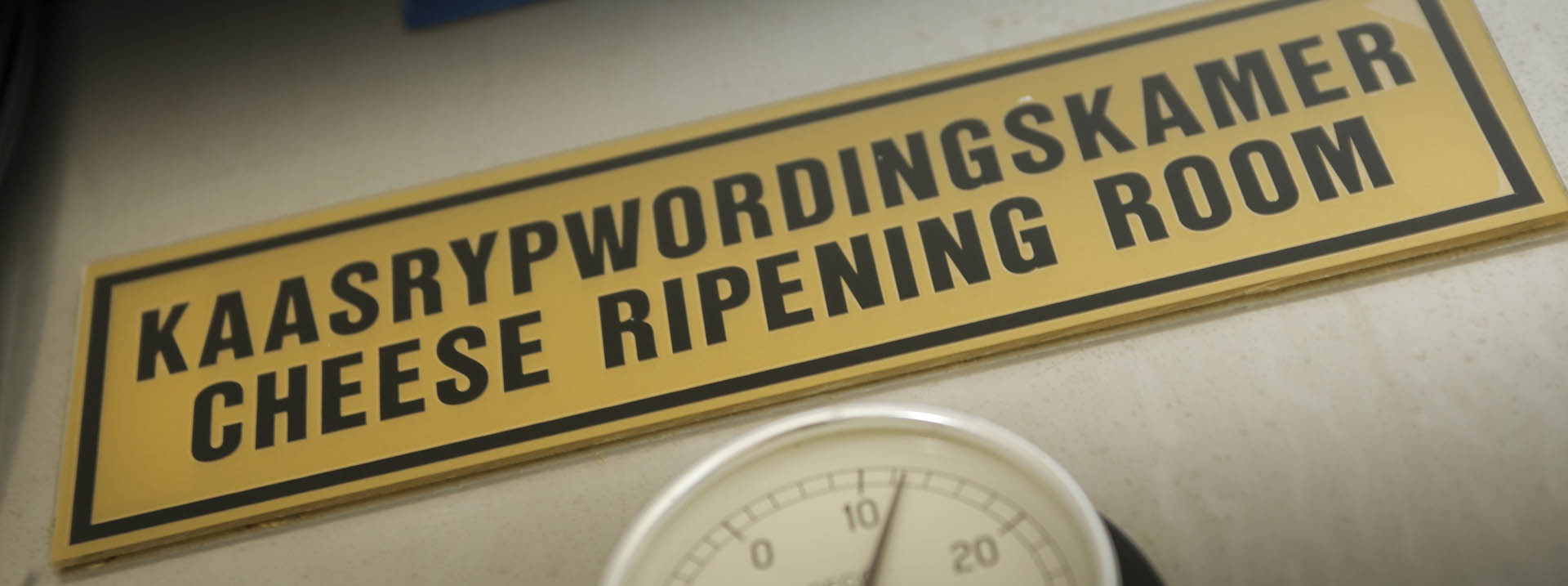

Cheesemaking includes heating and salting the cheese curd. Any changes in temperature may lead to significant variations in the end product.

Control over these aspects is crucial to the transformation of the cheese. Cheesemaking as art and craft, manages the cheese as it constantly undergoes minor shifts to accommodate the changing ingredients, mainly milk. This enables cheesemakers to create an increasing range of custom-made cheese types and styles.

Introduction

A classic example of food preservation, cheesemaking dates back to at least 3 000 BC. Refer to the SAY CHEESE! A BRIEF HISTORY section, for more on the history of cheese.

Preservation of the fat and protein within milk, its most important constituents, exploits two of the classical principles of food preservation:

- Lactic acid fermentation, and

- Reduction of water activity through removal of water (whey), and addition of salt, where applicable.

Establishment of a low redox potential as a result of bacterial growth contributes to the storage stability of cheese.

Principles of Cheesemaking

The basic principles of cheesemaking are the same for nearly all varieties of cheese.

The process involves the removal of water (whey) from milk resulting in a six to tenfold concentration of the protein, fat, minerals and vitamins, through the formation of a protein coagulum which shrinks to expel whey.

Processes involved are acidification, coagulation, cooking, salting, dehydration (syneresis), molding (shaping), pressing, packaging and maturation (storage).

Cheesemaking and Pasteurisation

The production of most varieties of mass-produced cheese includes pasteurisation. Pasteurisation of milk kills nearly all microorganisms present, including harmful bacteria, yeasts and coliforms. Therefore, both the bad and the good are killed.

St.Dairy uses a method called thermisation/pasteurisation. This method eliminates harmful microorganisms, keeping most of the probiotic microorganisms alive. Also, through this method, desired product outcomes are achieved.

Lactic acid-producing ‘starter’ cultures are added to facilitate the process.

There is a clear difference in the flavour and texture of cheese made from raw milk, meaning milk as it was received from Mother Nature, and mass-produced cheeses.

A Little More About

St.Dairy’s Process

Acidification:

Acidification of milk is important for the proper release of whey from cheese curd, to control growth of undesirable organisms. Most cheeses are made with lactic acid-producing ‘starter’ cultures. These probiotic cultures ensure a healthy mix of microflora in the final product.

Coagulation:

Coagulation of the casein fraction of the milk to form a gel, is achieved by lowering the pH and adding rennet, a complex of enzymes.

Syneresis

Syneresis (shrinking) of the coagulum (curd) happens through continuous rennet action. Moisture (mostly whey) is expelled, accelerated by e.g. cutting, stirring, cooking, salting or curd pressing.

Curd Manipulation

Heat treatments are applied to cheese curd at various times to achieve desired maturation pathways. This facilitates the production of St.Dairy’s variety of cheeses.

Salt

Added as a flavourant and preservative, at various times, affecting the texture and flavour of the cheese.